Experience cutting-edge precision and efficiency with TechCorr's 3D Laser Scanning Solutions.

Industrial 3D Laser Scanning

TechCorr’s extensive experience, spanning thousands of field tests on diverse industrial assets including pressure vessels, storage tanks, pipelines, and more, has culminated in the development of sophisticated knowledge-based systems like CORPAC™, VPAC™, MONPAC™, POWER-PAC™, and TANKPAC™. These systems, engineered by Physical Acoustics Corporation (PAC), a member of TechCorr Products & Systems division, epitomize innovation and reliability. Under ISO-9001 Certification, our state-of-the-art AE systems and sensors undergo meticulous calibration and maintenance by TechCorr’ highly trained staff, ensuring precision and accuracy in every inspection.

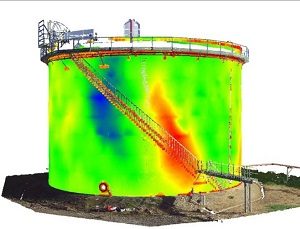

Specifically tailored for Above Ground Storage Tank (AST) applications, TechCorr’s AET methodology provides real-time, 100% volumetric monitoring, enabling swift detection of structural defects. Employing advanced low and high-frequency receivers, our AET system captures and models acoustic signals, facilitating in-depth analysis through proprietary auto-analysis and artificial intelligence software. This analysis reveals the type, location, and severity of damage mechanisms such as bottom side and top side corrosion, weld cracking, and embrittlement. While AET may not fulfill API 653 requirements, its role as a powerful screening tool aids in maintenance prioritization. Furthermore, when integrated with our In-Service Robotic Tank floor inspection service, AET facilitates deferral of out-of-service tank inspections, optimizing asset management strategies while minimizing operational disruptions.

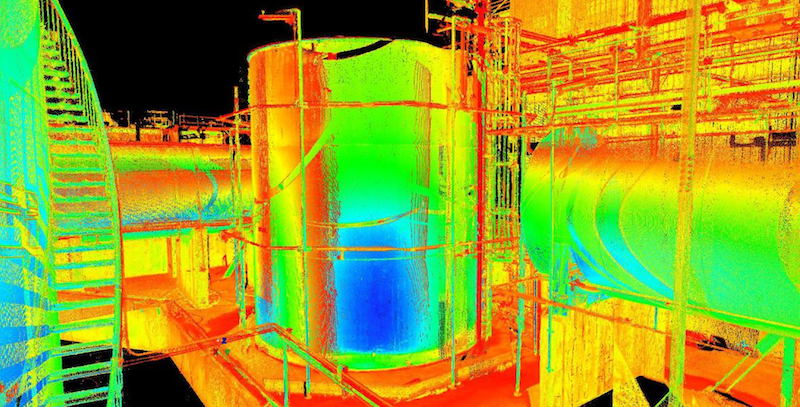

Optimize Project Timelines & Minimize Operational Disruptions

Streamline Operations & Minimize Errors

FAQs (Learn More)

-

Ensuring Operational Integrity: TechCorr’s Post-Fire Hardness Test Analysis

-

Safeguarding Asset Integrity: Advanced NDT Inspection of Critical Gas Oil Piping System

-

Safeguarding Asset Integrity through Advanced NDT: TechCorr’s NAFTA Pipeline System Assessment

-

Forensic Failure Analysis: Unraveling the Causes of a Refinery Fire Incident

-

Horizontal Recontracting Drum Postfire Assessment

-

NDT Inspection of a Kerosene Piping System

-

Ensuring Asset Integrity Post-Fire: TechCorr’s Horizontal Drum Vessel Inspection

-

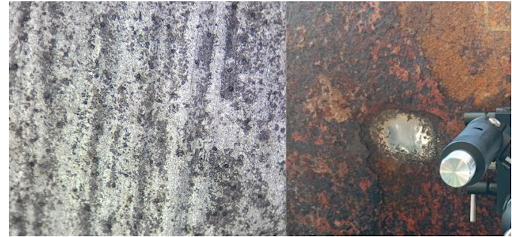

Corrosion Under Insulation (CUI) Detection and Repair Techniques

-

Postfire Metallographic Testing Analysis

-

Deploying Total Focusing Method for Critical Bolt Inspection