Experience cutting-edge precision and efficiency with TechCorr's 3D Laser Scanning Solutions.

Ultrasonic Tank Wall B-Scan Crawler

Optimize Project Timelines & Minimize Operational Disruptions

Streamline Project Success with Comprehensive Reporting

A Cornerstone of Tank Inspection

- Technical Details

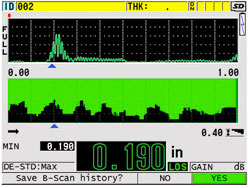

The B-scan Ultrasonic scanners provide a two-dimensional graphics presentation, plotting the travel time of ultrasonic pulses against the linear position of the transducer. This results in a detailed B-scan image that offers insights into both the size and depth of material flaws. The system is equipped with a complete UT crawler system, high-resolution B-scan imaging capabilities, and full recording of waveform data up to 30 meters distance. With battery-powered operation and no requirement for couplant or paint removal, the B-Scan Buggy ensures ease of use and minimal disruption to operations. Furthermore, the system's permanently stored data facilitates recall for trend forecasting in Risk-Based Inspection (RBI) and Remaining Life Assessment (RLA), contributing to reduced maintenance costs and improved safety outcomes.