Experience cutting-edge precision and efficiency with TechCorr's 3D Laser Scanning Solutions.

Guided Wave Ultrasonic Testing

Guided Wave Ultrasonic Testing (GWUT), Testing powerful non-destructive testing (NDT) technique utilized by TechCorr's Advanced NDT

Streamline Project Success with

Comprehensive Reporting

A Cornerstone of Tank Inspection

- Application Capabilities

- How it Works

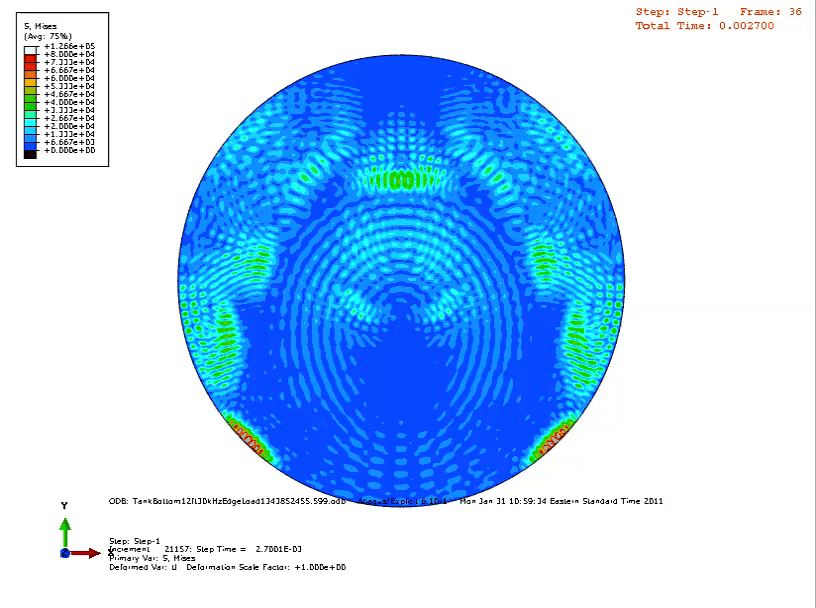

GWUT offers a wide range of applications, including inspection of buried and insulated pipes, anchor rods, boiler tubes, and road and rail crossings. Its capabilities include the inspection of 100% of the pipe or rod volume, rapid identification of corrosion damage in buried or covered structures, detection of corrosion and other defects, monitoring for corrosion over time, and the collection of corrosion data in difficult-to-access areas. By providing comprehensive coverage of the pipe wall without the need for insulation or coating removal, GWUT enables rapid screening of assets, allowing for quick identification of areas requiring further inspection using complementary NDT techniques.

Transducer rings are affixed to the external surface of the structure, facilitating the coupling of piezoelectric transducer elements to the pipe or rod under inspection. This setup enables the examination of long lengths of pipe or rod from a single location, making it particularly suitable for inspecting challenging areas such as buried or insulated piping with ease and minimal surface preparation.