THREE Dimensional Asset Profile Mapping

Experience cutting-edge precision and efficiency with TechCorr's 3D Laser Scanning Solutions.

For more than 30 years, Byron Group has earned one of the finest reputations across the globe for construction engineering service that achieve our client’s vision

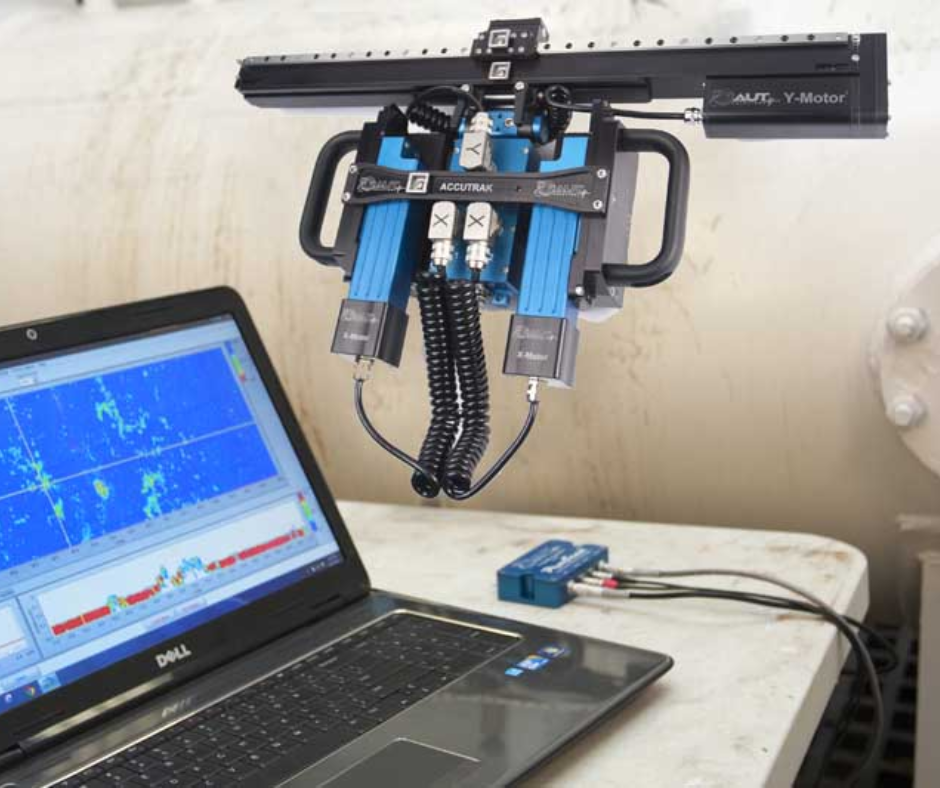

Automated Corrosion Mapping

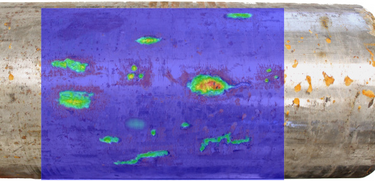

Employing state-of-the-art Automated Corrosion Mapping systems integrated with robotic scanners, TechCorr ensures rapid and comprehensive assessment of equipment condition across various industrial sectors. Commonly known as AUT Corrosion Mapping or C-Map, these systems facilitate real-time acquisition of wall thickness data over extensive areas of vessels and piping while operations continue uninterrupted. Our automated imaging technology swiftly identifies areas of concern, enabling precise localization of potential corrosion-related issues. With the capability to inspect 20-30 square meters per standard work day, our Automated Corrosion Mapping solutions offer unparalleled efficiency and reliability.

Optimize Project Timelines & Minimize Operational Disruptions

Automated corrosion mapping, leveraging advanced ultrasonic techniques, revolutionizes the inspection process by providing a comprehensive surface scan of equipment while simultaneously producing detailed corrosion maps. These systems, commonly referred to as AUT Corrosion Mapping or C-Map, utilize robotic scanners to acquire real-time wall thickness data over large areas of vessels and piping, enabling continuous operation during assessment.

Streamline Project Success with Comprehensive Reporting

All inspections and findings are meticulously documented in a comprehensive electronic report. This report includes summarized recommendations, calculations, API checklist items, CAD drawings, and high-quality photos, providing you with clear insights into the condition of your assets.

A Cornerstone of Tank Inspection

- Technical Details

The technology, exemplified by TechCorr's integration of Automated Corrosion Mapping with RSTRENG® software, facilitates precise sizing of defects, including length, width, depth, and orientation, thereby ensuring a thorough understanding of equipment integrity. Notably, the use of RSTRENG® software enables Fitness-for-Service (FFS) assessments, recognized and accepted by regulatory bodies such as the U.S. Department of Transportation. With over 25 years of experience in delivering advanced ultrasonic technology, TechCorr remains at the forefront of ensuring the safety and reliability of plant equipment, offering unparalleled quality and integrity in every inspection endeavor.