In the wake of a significant industrial fire, comprehensive evaluations are essential to ascertain the degree of destruction and identify which equipment is salvageable or requires replacement. In these assessments, advanced non-destructive testing (NDT) and metallographic techniques are essential.

The Challenge: Assess how the fire affected the base metals and welds’ microstructure in different components. Our methodology, which was based on the API 579 assessment criteria, concentrated on metallographic replicas at significant exposure spots.

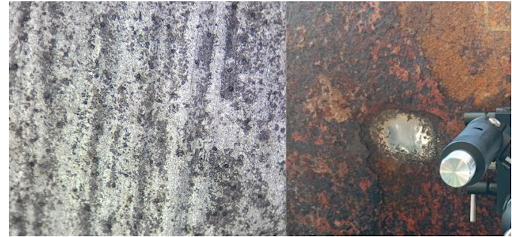

Field metallographic tests were carried out by TechCorr’s experts on a number of crucial parts, such as the Exchanger E-12, D1-Drum, D-82 Recontacting Drum, E-85 Exchanger, T-3 Debutanizer, E-4 Overhead Condenser, and associated pipework. A comprehensive microstructural analysis was performed on each component to identify any alterations brought about by heat exposure. Strategic test site selection was used to compare regions treated to radiant heat with those directly exposed to the fire.

The results of the metallographic study showed that there were no notable microstructural changes, and both the base metal and the weld structures were preserved. The fire side shell material of Exchanger E-12, for example, showed no symptoms of thermal degradation and retained a typical pearlite and ferrite structure. The heat-affected zone of the shell also showed fine grains typical of unaffected portions. In a similar vein, the boot and shell parts of the D1-Drum exhibited identical microstructures on both the fire-exposed and opposite sides, suggesting robustness to the heat event. A similar pattern was seen in the D-82 Recontacting Drum, where the microstructural integrity of both fire-exposed and non-exposed sections was maintained. The idea that the maximum temperature during the fire did not surpass critical thresholds was supported by analysis of the E-85 Exchanger and T-3 Debutanizer, which revealed no signs of microstructural deterioration.

According to the in-depth metallographic analysis, the temperatures at which the fire occurred did not rise above 600°C, guaranteeing the materials’ structural integrity. This discovery is significant because it highlights how resilient the components are to unforeseen heat stress. Our ability to provide accurate and trustworthy assessments enables our clients to make well-informed decisions about the upkeep and use of their assets. This example shows how TechCorr uses cutting-edge NDT methods to maintain the highest industry standards for efficiency and safety.

TechCorr is a leader in innovation and dependability in the asset management industry, constantly pushing the boundaries to guarantee the highest level of integrity for vital infrastructure. Our dedication to quality not only resolves problems right away but also establishes standards for future business operations.